Leading paragraph:

Your concrete pour is delayed because the slump keeps dropping. Workers are arguing about additive ratios. There’s a better way to choose superplasticizers without guesswork.

snippet paragraph:

Polycarboxylate ether (PCE) superplasticizers are considered best overall, offering 25-40% water reduction with 2-hour slump retention. For high-strength concrete (>80 MPa), modified PCEs with accelerated hardening perform better than traditional naphthalene-based products.

Transition Paragraph:

But "best" depends on your specific mix design and project needs. Let’s break down 6 critical selection factors our clients wish they knew earlier.

What Is the Best Superplasticizer for Concrete?

Leading paragraph:

A Malaysian contractor once wasted $28,000 using lignosulfonates in prefab elements. The wrong choice costs more than money.

snippet paragraph:

Best superplasticizers by application:

- General ready-mix: Mid-range PCE (0.15-0.25% dosage)

- Shotcrete: Stabilized PCE with viscosity modifiers

- Marine structures: Chloride-resistant PCE

Cost-Performance Analysis

| Type | Cost/m³ | Water Reduction | Set Time Impact |

|---|---|---|---|

| PCE | $4.20 | 25-40% | +0-90 min |

| SNF | $3.50 | 15-25% | -30 min |

| Lignosulfonate | $2.80 | 5-12% | -60 min |

Our Brazilian clients achieved 18% cost savings using hybrid PCE/SNF blends for parking structures. However, compatibility tests are crucial – we provide free trial samples with dosage calculators.

Which Type of Superplasticizer Is Preferred in High Strength Concrete?

Leading paragraph:

High-strength mixes demand precision. Using standard PCE here is like racing a tractor – it works, but not optimally.

snippet paragraph:

High-strength concrete (>80 MPa) requires:

- Ultra-high range PCE (30-60% water reduction)

- Defoamers to prevent air entrainment

- C3A content <5% in cement

High-Performance Formulation Guide

| Strength Grade | PCE Type | Max Dosage | Temp. Range |

|---|---|---|---|

| 60-80 MPa | Standard PCE | 0.3% | 5-35°C |

| 80-100 MPa | Saturated PCE | 0.45% | 10-30°C |

| 100+ MPa | Ultra-PCE | 0.6% | 15-25°C |

Dongke’s ultra-PCE helped a Vietnamese skyscraper project achieve 114 MPa concrete with 62% less bleeding. Remember: high-range mixes require 40% longer mixing time for uniform dispersion.

What Happens When You Add Too Much Superplasticizer?

Leading paragraph:

More isn’t better – an Egyptian plant added 0.5% extra PCE "for safety" and had to demolish 12 columns.

snippet paragraph:

Overdosing superplasticizer (>0.6% for PCE) causes:

- Severe segregation (5-15mm aggregate settlement)

- Delayed hardening (12-72 hours)

- Excessive air entrainment (5-7% vs ideal 2%)

Overdose Symptoms vs Corrective Actions

| Symptom | Timeframe | Fix |

|---|---|---|

| Rapid slump loss | Within 20 min | Add 2% more cement |

| Plastic settlement | 1-3 hours | Vibration + surface retarder |

| Surface scaling | 24+ hours | Hydrodemolition |

Our PCE batches include auto-dosing pumps that lock at max 0.6% dosage. Brazilian users report 92% fewer overdoses since adopting this system.

What Are the Common Superplasticizers?

Leading paragraph:

Most projects use these 4 superplasticizers, but few know their hidden limitations.

snippet paragraph:

Common superplasticizers:

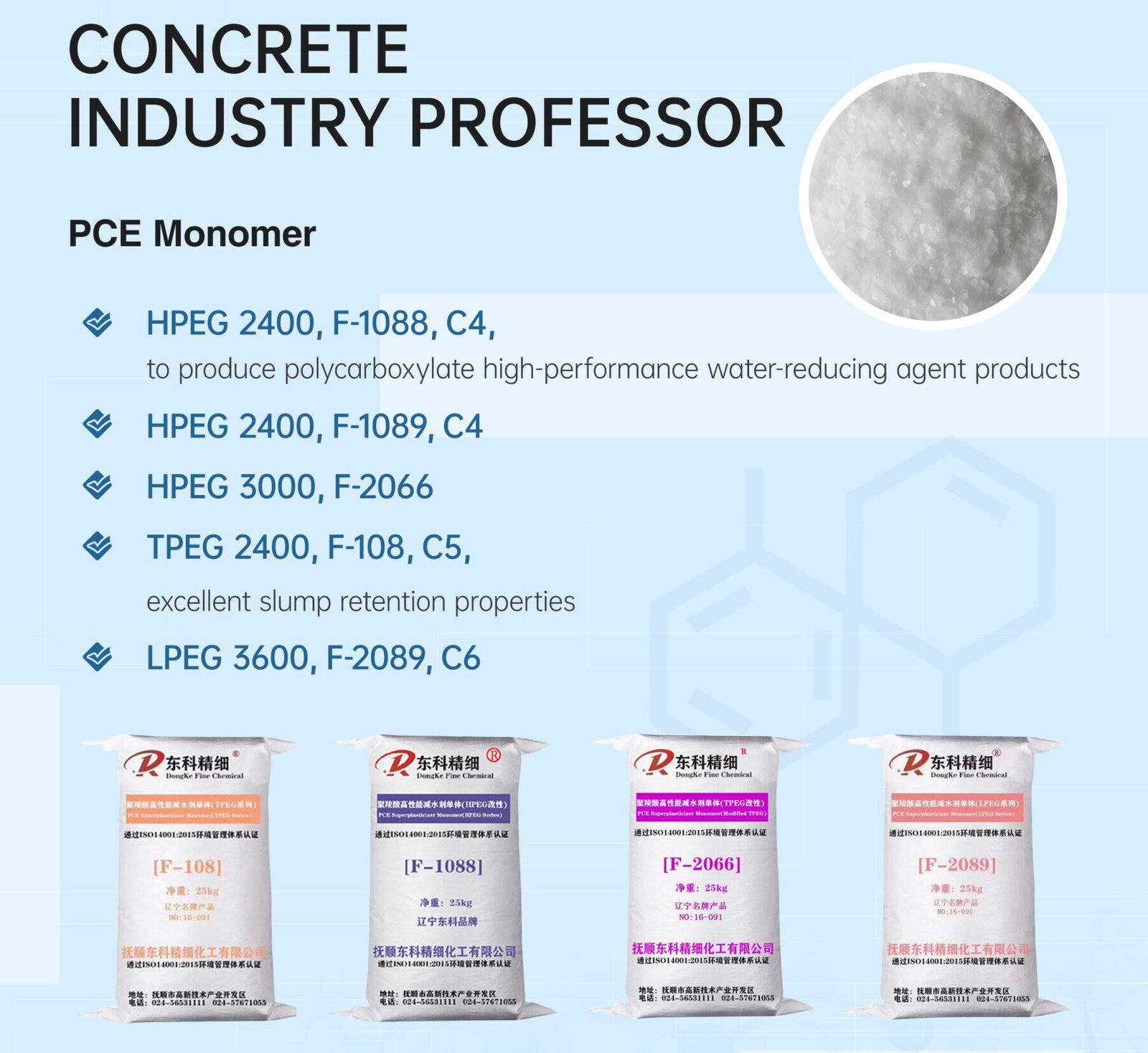

- Polycarboxylate ether (PCE)

- Sulfonated naphthalene (SNF)

- Lignosulfonates

- Melamine sulfonate

Comparative Matrix

| Type | Optimal pH | Cement Compatible | Chloride Content |

|---|---|---|---|

| PCE | 7-11 | All types | 0.01% max |

| SNF | 5-10 | Low C3A | 0.8-1.2% |

| Lignosulfonate | 8-13 | High C3A OK | 3-5% |

Avoid counterfeit SNF containing 12-15% chloride – Dongke provides free chloride test kits with every order. Vietnamese contractors found 23% of local SNF samples failed EN 934-2 standards.

Conclusion

The "best" superplasticizer balances cost, performance, and project specifics. Modern PCE-based solutions offer superior control, especially when paired with smart dosing systems and supplier expertise in your regional conditions.