Diethanol Isopropanolamine: A Versatile Additive for Multiple Industries

Diethanol isopropanolamine (DEIPA) is an organic compound belonging to the class of alkanolamines, chemicals that feature both hydroxyl (-OH) and amine (-NH) groups. These dual-functional groups make DEIPA a versatile compound with various applications in different industries, from cement production to surfactants and even in personal care products. As an additive that enhances performance in many chemical processes, DEIPA is becoming an essential component in modern industrial applications. In this article, we will explore DEIPA's chemical structure, key applications, and the benefits it offers to various industries.

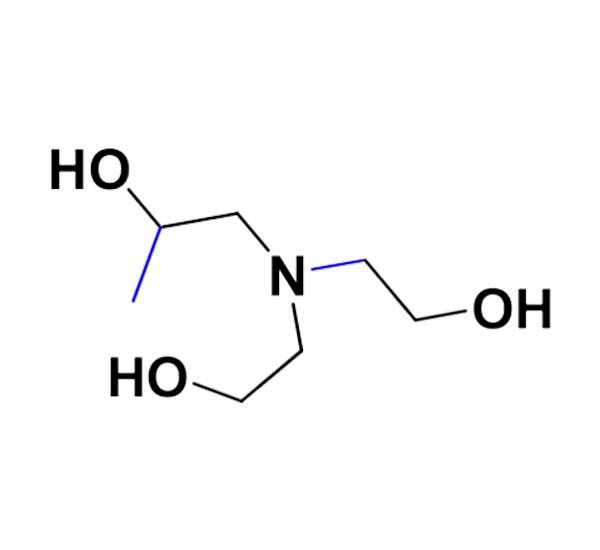

Chemical Structure and Properties of DEIPA

DEIPA (C7H17NO3) has a molecular structure that includes two hydroxyl groups and one amine group. This combination gives it both water-soluble and reactive properties, making it an effective agent in a variety of chemical formulations. At room temperature, DEIPA appears as a colorless to pale yellow liquid with a slight amine odor. It is fully miscible with water and polar solvents, which enhances its utility in aqueous systems.

Key properties of DEIPA include:

- Molecular Formula: C7H17NO3

- Molecular Weight: 163.22 g/mol

- Boiling Point: 247°C

- Density: 1.04 g/cm³

- Solubility: Completely soluble in water and other polar solvents

These properties make DEIPA a highly adaptable chemical that can be utilized in several industrial processes, providing both functional and economic benefits.

DEIPA in the Cement Industry

One of the most significant applications of DEIPA is in the cement industry, where it serves as a cement grinding aid and a performance enhancer. Grinding aids like DEIPA are added to the grinding process to reduce energy consumption, increase production efficiency, and improve the overall quality of the cement.

1. Cement Grinding Aid

During cement production, raw materials such as clinker are ground into a fine powder. Adding DEIPA to the grinding process helps prevent the cement particles from agglomerating or sticking together. This leads to smoother grinding, a reduction in the energy required for the grinding process, and an increase in mill output. By optimizing the grinding efficiency, DEIPA can also help reduce operating costs for cement manufacturers.

2. Performance Enhancer

DEIPA not only improves the grinding efficiency but also acts as a performance enhancer by increasing the early and final compressive strength of cement. This is achieved by accelerating the hydration of clinker particles and promoting the formation of calcium silicate hydrate (C-S-H), the primary binding phase in cement. This strength enhancement is particularly valuable in high-strength cement applications, where early strength gain is crucial for construction timelines.

DEIPA in Other Industrial Applications

In addition to its critical role in the cement industry, DEIPA is also employed in a range of other industries due to its multifunctional properties.

1. Surfactant Production

In the production of surfactants, DEIPA acts as an intermediate. Surfactants are compounds that lower surface tension between liquids or between a liquid and a solid, making them essential in cleaning products, detergents, and personal care products. DEIPA’s solubility and reactivity make it an excellent ingredient for creating stable, effective surfactant formulations. It helps improve the emulsifying properties of surfactants, enabling them to mix water and oil, which is vital for cleaning greasy surfaces.

2. Corrosion Inhibitor

DEIPA is also used as a corrosion inhibitor in metalworking fluids and lubricants. It forms a protective layer on the surface of metals, preventing oxidation and corrosion, which can extend the life of metal equipment and machinery. The use of DEIPA in corrosion inhibitors is particularly valuable in industries where metal surfaces are exposed to moisture, chemicals, and other corrosive substances.

3. pH Adjuster in Cosmetics

In the cosmetics and personal care industry, DEIPA is employed as a pH adjuster and emulsifier. Maintaining the correct pH is crucial in cosmetic formulations to ensure product stability and skin compatibility. DEIPA helps regulate the pH of products such as shampoos, lotions, and creams, preventing separation of ingredients and ensuring a smooth, even texture.

Environmental and Safety Considerations

While DEIPA is generally considered safe when used appropriately, certain precautions must be taken during its handling. Exposure to concentrated DEIPA can cause irritation to the skin, eyes, and respiratory system. Workers who handle DEIPA in industrial settings should use personal protective equipment (PPE), such as gloves, safety glasses, and protective clothing, to minimize the risk of exposure.

In terms of environmental impact, DEIPA is classified as biodegradable, meaning it will naturally break down over time without causing significant harm to the environment. However, as with any chemical, proper disposal methods should be followed to prevent contamination of water bodies or soil.

Conclusion

Diethanol isopropanolamine (DEIPA) is a highly versatile chemical that plays an essential role in various industries. Its primary application as a cement grinding aid and strength enhancer in the cement industry helps manufacturers improve production efficiency and product quality. Beyond cement, DEIPA is also utilized in surfactants, corrosion inhibitors, and cosmetic formulations, thanks to its ability to adjust pH levels and stabilize emulsions.

As industries continue to seek more efficient and environmentally friendly solutions, DEIPA's multifunctional properties make it a valuable chemical for diverse applications. Its adaptability and effectiveness ensure that it will remain a key ingredient in many industrial processes for years to come.